Tempered Glass Panel Thickness

How thick is the piece of glass that you need? (Note that the graphics are representations only and not the actual thickness.)Keep in mind that this glass can only handle temperatures up to 300-400 degrees, if your appliance produces more heat than this, you should look into ceramic glass panel options.

Tempered glass comes in the following thickness. These are the most common sizes for fireplace glass:

- 1/8" inch

- 3/16" inch

- 1/4" inch

The smallest size of tempered glass that we can make is 12" x 4" so sizing starts there. Standard glass is clear, if you need bronze or grey, specify in the order request box.

Give us a call at 217-223-0999

Tempered Glass Cut to Size in the USA

As well as proudly offering standard sizes from Illinois, USA, as one of the best tempered glass manufacturers we also offer custom tempered glass cutting.

Please be aware that tempered glass should NOT be used in an airtight wood stove, it also takes 10-14 business days for the tempered glass to be processed and tempered - the glass cannot be re-cut. For this reason, all tempered glass orders are final.

Why Order Your Tempered Glass Sheets From Woodstove Fireplace Glass?

Woodstove Fireplace Glass is the premier source for high-quality tempered glass panels. We offer a wide selection of sizes and thicknesses, ensuring you get the exact size you need for your project. Our tempered glass is heat-treated to resist cracking and shattering, making it a safe choice for your stove.

Additionally, our custom tempered glass cutting services allow you to get the exact size and shape you need, reducing waste and ensuring a perfect fit for your project. To learn more about our tempered glass cut to size in the USA, place an order, or please contact us today!

Delivery Information For Your Tempered Glass Sheet

The largest we can ship UPS is 36" x 36". If you need sizes bigger than this, or your glass has a pattern, please call us for a special quote.

All Tempered Glass Orders Take 10–14 Working Days to Process

Due to the nature of this glass, and the way it is made, all sales are final. All orders are custom cut; there can be no refunds once the glass is cut. It can take up to 14 days due to the glass being cut, "cooked" in a high-temperature oven, and then rapidly cooled. For cost reasons, this type of product is done in batches.

If you have any problems with your order, please notify us as soon as possible. If we need to replace an order, the original glass will be issued a pick-up ticket and sent back for us to apply for the credit.

When you order fireplace glass from woodstove-fireplaceglass.com, your trusted source for wood stove and fireplace door glass, we try to fill your order as quickly and accurately as possible.

The price will include U.P.S. ground shipping in the continental U.S. after you add your order to the shopping cart and enter your zip code. Then you will be shown the shipping charges.

All other shipping will have to be quoted.

Tempered Glass Panel FAQs

What is the difference between ceramic glass and tempered glass?

Tempered glass is regular glass that is "cooked" and "cooled" very rapidly to lock the glass molecules in place. This tempering process gives the final product a couple of unique features. The strength of the glass from impacts and the temperate range is increased. The newly tempered glass is then able to withstand temperatures up to about 400 degrees. It is used in low-temperature fireplace doors - like bi-fold doors, for this reason. It is much cheaper to produce than Ceramic glass products that can withstand such high temperatures.

Why is tempered glass called “safety glass?”

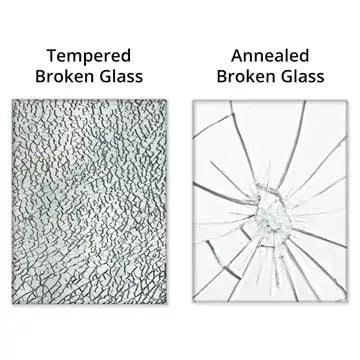

Tempered glass should be used when standard glass could pose a potential danger. It is four to five times stronger than normal glass and does not shatter into large chunks when broken. Manufactured through a process of extreme heating (tempering) and rapid cooling, tempered glass is significantly harder than regular glass.

The tempered glass is much harder to break when hit straight on. But if broken, this process causes it to shatter into small, oval-shaped pebbles. This eliminates the danger of sharp edges. This is why, along with its strength, this glass is often referred to as ‘safety glass.’ The tempering also raises the heat resistance up to about 400-500 degrees F. This is why this glass should be used in any situation where there is a danger of the glass breaking due to impact or extreme heat.

Our custom safety glass panel options are available in many different sizes and thicknesses. If you need a specific size, contact us for a custom quote.

Is this glass suitable as replacement glass for an oven door?

Yes, tempered glass is a suitable choice for a replacement oven door. Due to its high heat resistance of up to 400-500 degrees F, tempered glass is able to withstand the high temperatures generated within your oven while still providing you with the same clarity and visibility as standard glass.

What can I use tempered glass cutting for?

The thermal process that cures tempered glass also makes it heat resistant. Tempered glass is used to make the carafes in automatic coffee makers and the windows in ovens. Computer screens, skylights, door windows, tub enclosures, and shower doors are more examples of places you will find tempered glass. Building codes also require the windows of many public structures to be constructed from tempered glass.

Do you do custom tempered glass?

Yes, we do offer custom tempered glass options. We have a variety of sizes and thicknesses available to accommodate any project. We use only the highest quality glass for our tempered products. Our tempered glass is designed to be more durable and heat-resistant than standard glass, so it can handle higher temperatures without shattering or breaking. If you have a specific size or pattern, please contact us.

Will my glass have a "Watermark" on it?

Yes, According to the 2021 International Building Code (IBC), tempered glass must be permanently identified by the manufacturer, with the exception of tempered spandrel glass. The identification mark can be acid etched, sand blasted, ceramic fired, laser etched, or embossed. It can also be any type of marking that can't be removed without destroying the glass. Tempered glass may also have other markings, such as: Company branding: The manufacturer's logo and brand name Batch numbers: The batch number of the glass Traceability codes: Codes that help with traceability EN marks: Marks that comply with EN standards BSI kitemarks: Marks that comply with BSI standards in the UK For example, Andersen Windows etches an FX-number into the glass used on their Flexiframe, Arch, and Springline units. The FX-number is located in the corner of the glass, but not the same corner as the Andersen logo. For units made before 2002, the FX-number may be written on